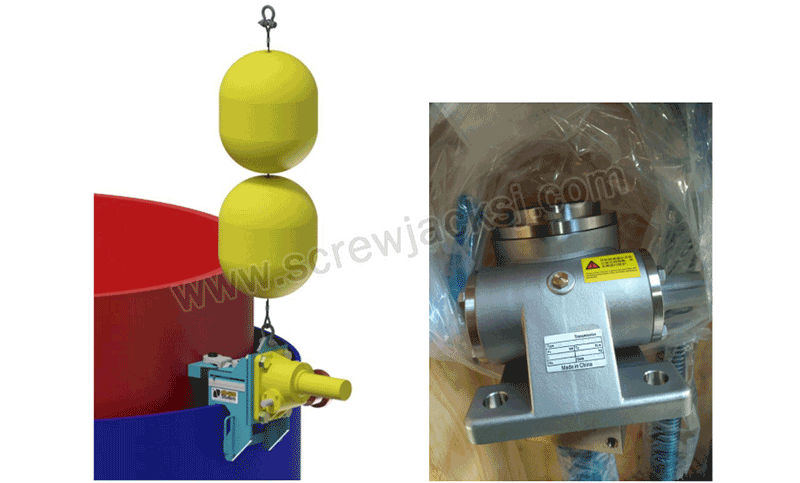

Customer application scenario: maximum depth of 60m below sea level, pressure at 5.9 bar. Needed Max. push force is 260KN, speed is 20mm/min. Frequency: 10-20 times a year.

Our solution: The customer can only use SIJIE's SJW-300 (300KN) screw jack with limited installation space. After SIJIE technical team's calculation, under the load of 260KN, the torque acting on the input shaft of the screw jack is 230N.m. Considering the stainless steel 316 material, which is rigid and weak to withstand the torque, we use the high-strength Duplex stainless steel, thus solving the problem of a possible fracture of the input shaft. Regarding the pressure, we will inject the pressure inside the stainless steel screw jack so that the internal pressure and the pressure of the seabed are approximately equal. In order to make the stainless steel screw jack have a longer service life, all our parts are from famous brands, we use WKF from Taiwan for oil seal, we use high-performance ceramic bearings, and we use 10-1 phosphor bronze for the worm wheels.